Stopend with Water Stop

The Hydraulic Stopend with Water Stop equipments which were developed and patented by Raga Makina Sanayi, provide water-tightness with water-holding band concreting process.

Cut-Off Wall With Stopend With Water Stop Application

Cut-off wall systems are shoring systems applied to ensure the impermeability of the shoring system that will be constructed under high ground water table. The main function of this shoring system is to prevent ground water intrusion into the excavation, which can be implemented with diaphragm walls and intersecting bored piles.

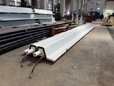

- The pannel should be opened with the diaphragm wall machine within the project scope. It requires to replace Stop-Ends with water-holding band to opened pannel. Water-holding parts should be replaced on hydraulic stop-ends initially.

- The iron equipment should be replaced in the opened pannel.

- Concrete should be poured in the iron equipment.

- The pannel wall should be digged from the end of both sides of concrete poured hydraulic stop-end

- After opening panels to both sides, stop-end separates itself by hydraulic pistons. The water-holding band should be stayed on the wall.

- Hydraulic water stop with stopends can be easily taken from the well.

- The water stop with stopends that taken from the well, should be bringed down through the same well by leaning against the wall. The water-holding bands should also be placed.

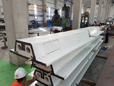

- The iron equipment should be placed on both pannels.

- Concrete should be poured on the pannels which the iron equipment's placed on. It can be repeated in needed quantity. Water-holding bands provide water-tightness between each pannel as shown in the image above.

| Document Name | Date | Show |

|---|

| Description | Date | Play |

|---|